Add to Cart

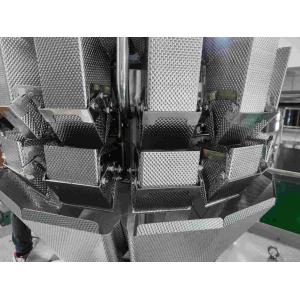

SUS304 auto mult-ihead weigher for raisins nut and dog biscuits

Features:

1. high accuracy

2. modular design

3. food-grade 304 stainless steel structure

4. Easy installation and operation

5. IP65, Waterproof

Quick questions:

1. What certifications do your machines have?

Generally, our machines are CE certified, and we aim to follow best-in-class manufacturing processes across the board.

2. How does a Multi-Head Weigher work?

A multi-head weigher–also sometimes known as a combination weigher or multi-head scale–is a high-speed, high accuracy weighing machine which that is commonly used in the food industry as well as other packaging applications.

Each machine contains multiple weighing heads, each with its own load cell, which is used in combination. Based on the target weight, the software of the scale chooses which scale buckets (when added together) combine to reach the desired weight.

3. What parts are included within a weighing and packaging system?

It depends on your needs. Feeding hopper, inclined conveyor, multi-head weigher, support platform, vertical form fill seal packing machine, take away conveyor, rotary collection tables.

Specifications:

| Model | TY-ZHY10M25-01-11 |

| Weighing range | 20-1000g |

| Accuracy | x (0.5) |

| Min. scale interval | 0.1g |

| Max. weighing speed | 60 p/M |

| Volume of weighing hopper | 2.5L |

| Control system | PLC or MCU |

| HMI | 10'' touch screen |

| Power supply | AC220V ±10% @50Hz/60Hz, 1.5KW |

| Packing dimension (L*W*H) | 1060 x 1370 x 1205mm |

| Gross weight | 385kgs |

| Model | TY-ZHY14M-25-01-11 |

| Weighing range | 20-1500g |

| Accuracy | x (0.5) |

| Min. scale interval | 0.1g |

| Max. weighing speed | 120 p/M |

| Volume of weighing hopper | 2.5L |

| Control system | MCU |

| HMI | 10'' touch screen |

| Power supply | AC220V ±10% @50Hz/60Hz, 1.5KW |

| Packing dimension (L*W*H) | 1100 x 1140 x 1857mm |

| Gross weight | 500kgs |